Comparing Work Instructions and SOP: Which is More Effective?

Iryna Smuk • 24 Jun 2024

Iryna Smuk • 24 Jun 2024

It is more important than ever to have incredibly clear business processes and procedures in a world where complexity is only growing. Every organization relies on efficient processes to function smoothly. For this reason, a lot of companies decide to write SOP vs Work Instruction (WI) to document their workflows.

Although they have different uses, work instructions, and standard operating procedures are both useful instruments for standardization and quality control.

So, let’s explore the key differences between SOP vs WI, its importance in achieving operational excellence and which is more effective for your business.

Definition of Terms

Work instructions (WIs) are detailed, step-by-step instructions aimed at executing a specific task. They describe clear and precise steps on how to perform a particular job or operation. WIs basically involve one individual with a designated role within a specific business unit. Furthermore, work Instruction is often accompanied by visuals, diagrams, or illustrations to enhance understanding and ensure consistency in execution.

Standard operating procedures (SOPs) refer to a set of instructions compiled by an organization to guide workers step-by-step on how to carry out routine operations efficiently and consistently. SOP encompasses more than one task, incorporating multiple work instructions and engaging various roles and departments.

However, to clearly define an SOP, we must first distinguish what’s the difference between a process and a procedure:

- A process entails a sequence of actions or steps aimed at achieving a particular outcome.

- A procedure outlines the precise method for executing a process. It offers a more granular explanation of a process.

That’s why, an SOP serves as the formal documentation, offering a broad overview of the activity as well as delving into specifics such as the individuals involved and the resources required for its completion.

Purpose and Scope: WIs vs SOPs

The primary purpose of work instruction is to ensure consistency and quality of work. They break down complex processes into manageable steps, offering employees clear instructions on what needs to be done, how it should be done, and in what sequence.

By providing a systematic approach to task completion, such instructions help minimize errors, reduce variability in outcomes, and enhance overall efficiency and quality. WIs also facilitate training and skill development among employees, enabling them to perform tasks with precision and confidence.

Standard operating procedure plays a fundamental role in standardizing procedures across the organization to ensure consistency and compliance with internal policies, industry regulations, as well as quality standards. SOPs lay out the prescribed methods, protocols, and best practices for carrying out routine operations, ensuring uniformity in approach across different departments, teams, or locations.

By establishing clear work guidelines and protocols, SOPs help mitigate risks, enhance operational efficiency, and maintain a high level of quality and compliance throughout the organization. Overall, they serve as a reference point for employees, providing standardized process maps for executing various tasks and operations in alignment with organizational objectives and regulatory requirements.

Detail and Complexity: WIs vs SOPs

The key distinction between WIs and SOPs lies in their level of detail. Work instructions are primarily geared towards aiding the daily functions of a business, whereas SOPs contribute to making processes more organized from a managerial perspective.

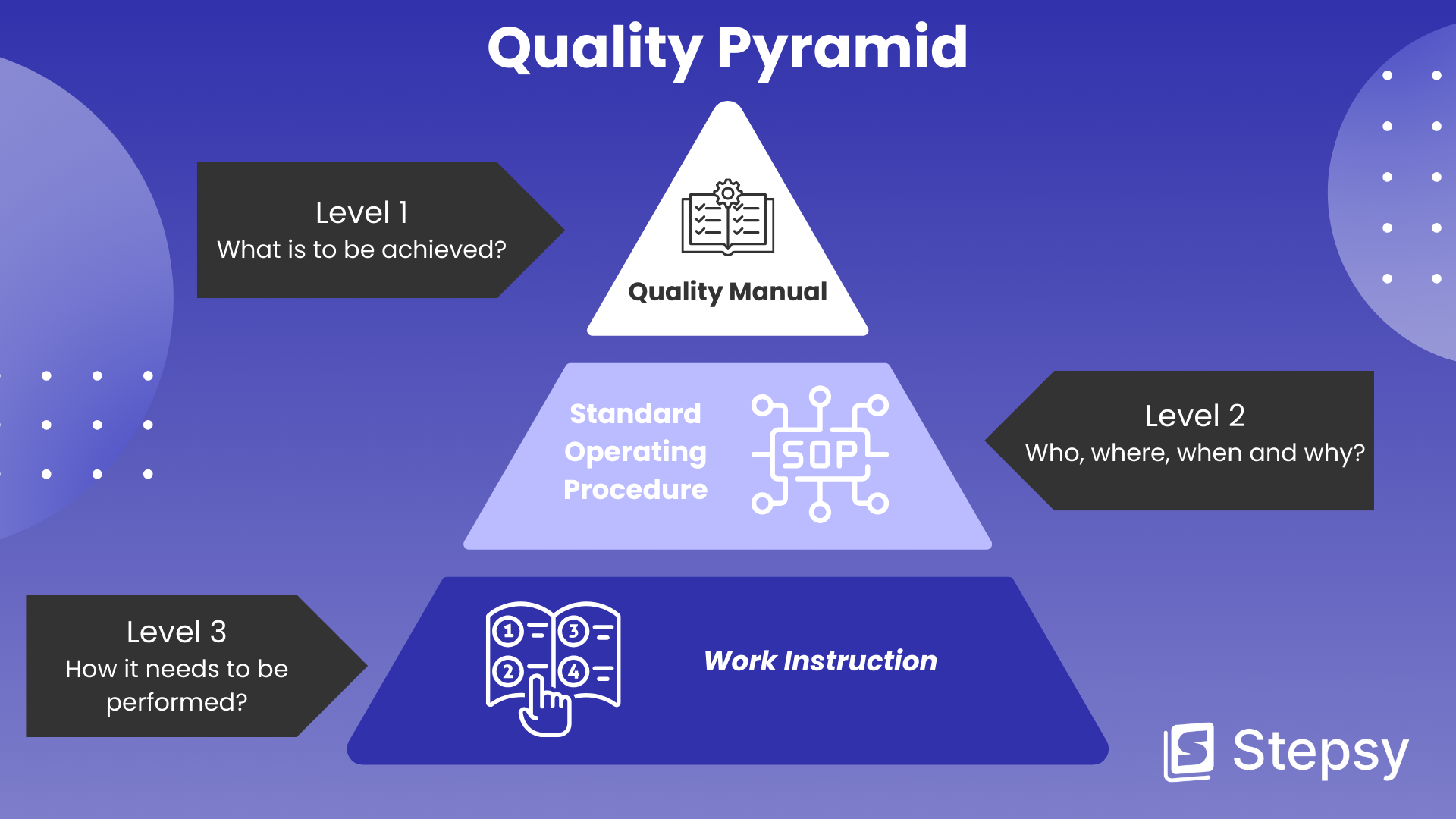

SOPs together with WIs are grouped inside a hierarchy of procedural documents in a quality management system. At the first level are quality manuals, which offer a structure for responsibilities, aims, and objectives. Then, SOPs and task instructions compose the second and third levels, respectively.

SOPs typically outline the following:

- The overall purpose of the process: What is the goal this process aims to achieve?

- The key steps involved: A high-level breakdown of the major stages in the process.

- Roles and responsibilities: Who is accountable for each step?

- General guidelines and best practices: Important considerations for completing the process effectively.

SOPs are concise and focus on the “who”, “where”, “when” and “why” of a process. This makes them easier to create and understand for a broader audience. However, for intricate tasks within an SOP, additional guidance might be needed.

This is where WIs step in. Detailed work instructions show the exact steps involved, including:

- The specific tools and materials required.

- Detailed instructions for each step, often phrased in a clear, sequential manner.

- Visual aids such as diagrams or pictures.

Generally, they require more effort to create and maintain. The level of detail necessitates a deeper understanding of the specific task as well as the ability to translate it into clear, actionable steps.

Use Cases

| SOPs Excel When Used | Work Instructions Excel When Used |

| To confirm that tasks or processes are completed consistently and accurately | To guarantee the quality of processes |

| To delegate obligations and accountability for specific tasks | To ensure the organization of project execution |

| To communicate roles and responsibilities across departments | To show how to do intricate tasks that require precise execution |

| To aid in troubleshooting and find solutions | To manage the workflow of processes |

| To initiate ongoing process improvement | To guide IT and software development, including coding, system administration, and cybersecurity measures. |

| To train workers | To explain setting up software applications |

| To streamline the process of onboarding of new employees | To provide safety protocols |

Advantages and Disadvantages: WIs vs SOPs

Advantages of Work Instructions

- Clarity: Clear instructions can reduce ambiguity and interpretation, in order to enhance understanding as well as minimize errors.

- Quality Control: Work instructions help maintain consistency and quality in task execution, ensuring uniformity in outcomes.

- Reduced Training Time: New hires can quickly grasp complex tasks with clear, step-by-step guidance, accelerating their onboarding process and saving time.

- Safety: WIs can help mitigate risks associated with intricate tasks.

However, work instructions have limitations have some limitations. Its lack of flexibility to accommodate variations or exceptions in task execution may lead to inefficiencies in certain situations. They can also limit creativity because they prescribe specific steps. Moreover, in cases when automatization of the creation of detailed instructions is not used, it can be time-consuming.

Advantages of Standard Operating Procedures

- Compliance: SOPs ensure compliance with regulatory requirements, industry standards, and internal policies, reducing the risk of non-compliance.

- Collaboration: SOPs can foster better understanding and communication across departments.

- Standardization: SOPs establish standardized procedures across the organization, promoting consistency and uniformity in operations

- Risk Management: SOPs help mitigate risks by outlining protocols for handling emergencies in order to ensure employee safety, and minimize operational disruptions.

Despite their benefits, SOPs also have some limitations. They might not provide sufficient guidance for intricate tasks, potentially leading to inconsistencies in execution. Such documentation mainly focuses on the overall process and doesn’t offer enough detail for effective ways of training. Additionally, the manual creation of SOPs can be a tedious and time-consuming job.

Implementation and Training: WIs vs SOPs

Work instructions are generally implemented at the operational level within an organization. They are usually made by subject matter experts or experienced employees who know the job well. After making them, WIs are disseminated to relevant workers through various means, such as training sessions, digital platforms, or printed manuals. Workers should then follow these step-by-step guides to complete a task and keep the quality consistent.

Depending on the complexity of the tasks involved, training for WIs may include classroom instruction, on-the-job training, simulations, or e-learning modules. It also may be necessary to perform regular reinforcement and refresher training to boost learning as well as address any changes or updates to processes or procedures over time.

Standard operating procedures, on the other hand, are implemented at a broader organizational level. Cross-functional teams, comprising representatives from various departments such as operations, quality assurance, compliance, and legal, typically develop SOPs. Once created, relevant stakeholders receive SOPs through training sessions, documentation repositories, or intranet portals. In brief, they use SOPs as a reference guide, outlining the prescribed methods and protocols for performing routine operations in alignment with organizational objectives and regulatory requirements.

SOP training may cover compliance requirements, quality standards, and regulatory considerations relevant to specific processes. Training for SOPs should emphasize the importance of adhering to established procedures, maintaining documentation integrity, as well as reporting any deviations or discrepancies encountered during task execution.

Tips to get the most out of SOPs and WIs

- Keep SOPs and WIs up-to-date: Regularly review and update them to reflect any shifts in procedures, regulations, or best practices. Keep everyone informed about those changes.

- Give everyone easy access: Store them in a central location, such as a digital platform, where they’re searchable and well-organized.

- Get employee feedback: Create channels for employees to suggest improvements and provide feedback on SOPs and WIs. Use this input to make the documents clearer and more helpful.

- Continuously improve. Utilize them as a springboard for process improvement initiatives. Likewise, encourage workers to identify areas for enhancement and propose changes.

Choosing Between Work Instructions and SOPs

So, how do you choose the right tool for your organization? Here are some key criteria to consider:

| Criteria | WIs | SOPs |

| Task Complexity | Require detailed, step-by-step guidance | Suited for standardizing broader processes or workflows |

| Level of Detail | Offer granular instructions for individual tasks | Provide a broader overview of processes |

| Compliance Requirements | Focus more on operational efficiency and consistency | Ensure compliance with industry regulations, standards, and internal policies |

| Training Needs | May require more hands-on training to ensure employees understanding | May necessitate broader training on organizational processes, compliance requirements, and quality standards |

| Flexibility | May offer more flexibility to accommodate variations in task execution | May be more rigid due to standardization requirements and compliance considerations |

Thus, only you can determine what works best for your organization in terms of SOP vs work instruction. Ultimately, the organization should align the decision with its goals, culture, and structure, as well as the specific requirements of the task or process. So, carefully consider these factors and select the most appropriate documentation approach to drive success.

Conclusion

Hence, clear and effective process documentation is undoubtedly the backbone of any well-functioning organization. Work instructions provide the meticulous detail required for intricate tasks, ensuring consistent and high-quality output. Standard operating procedures, on the other hand, offer a high-level roadmap, fostering collaboration as well as streamlining overall process flow.

Understanding the differences between SOP and work instruction, as well as their advantages, disadvantages, and implementation considerations, is key to making informed decisions that align with organizational objectives and requirements.